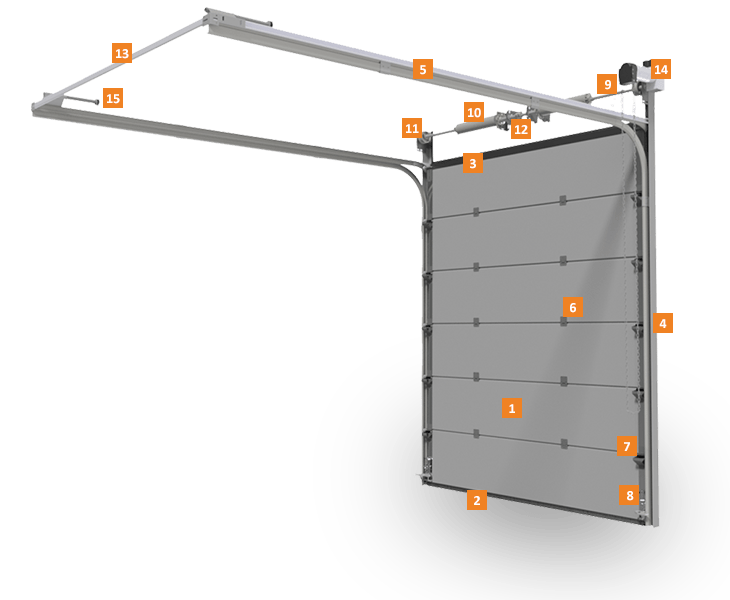

The leaf of the industrial door consists of panels 500 and 610 mm high made of hot-dip galvanised sheets. The 40 mm thick panels are filled with CFC-free polyurethane foam. On the outside, the panels are coated with paint or veneer. All panels are finished with galvanised sheet metal fittings and aluminium profiles. A gasket is fitted in the lower panel adjacent to the substrate. In the upper panel, the seal is mounted on the panel or to the lintel. In addition, the industrial door is sealed around the entire perimeter, which in combination with the warm panels guarantees excellent thermal and acoustic insulation. A „finger protection” system is used at the junction of the panels to protect the user from finger trapping. The guides have been shaped in such a way as to prevent unwanted movement of the bearing rollers, which greatly enhances safety.

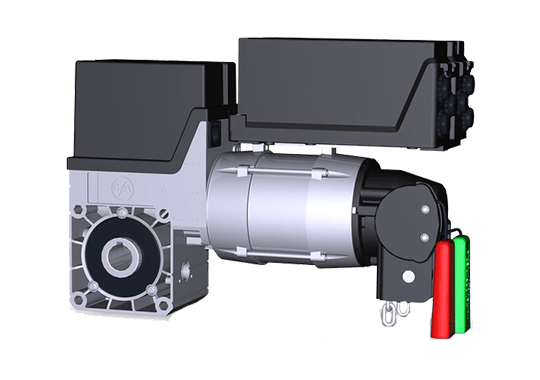

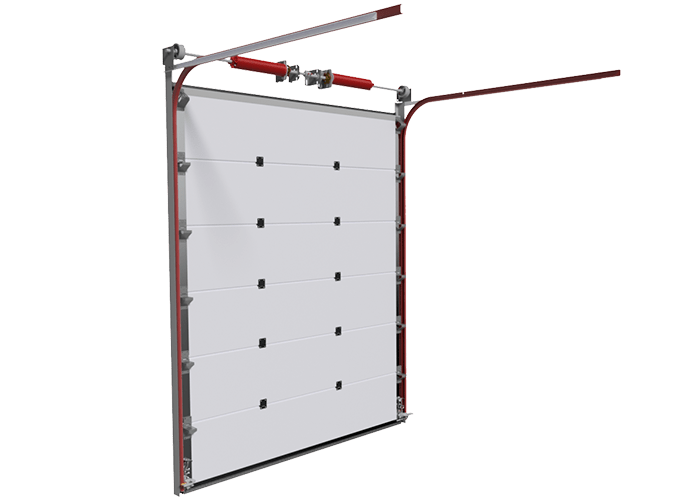

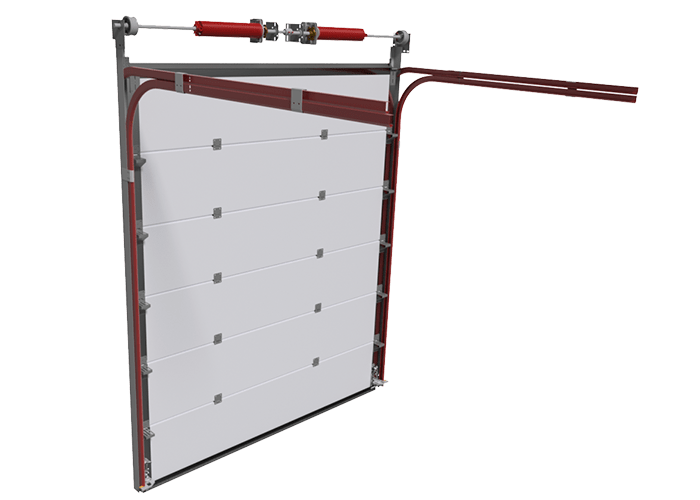

Standard drive (S)

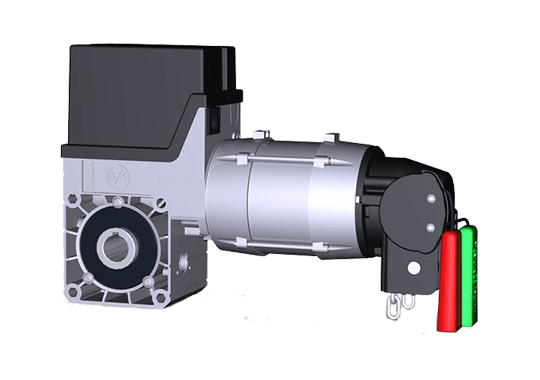

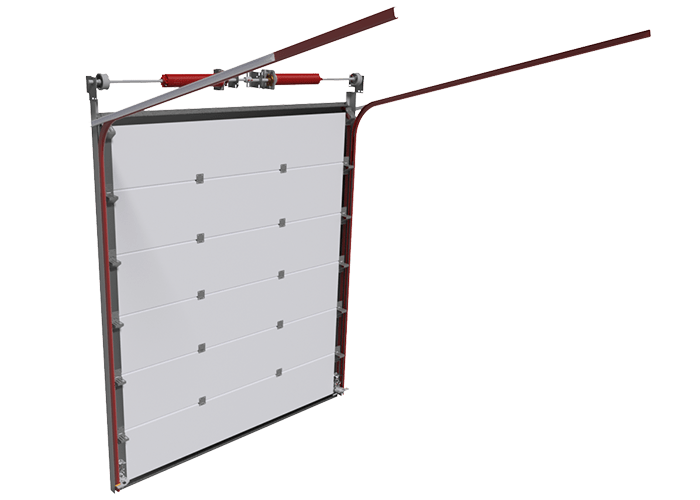

Driving high (H)

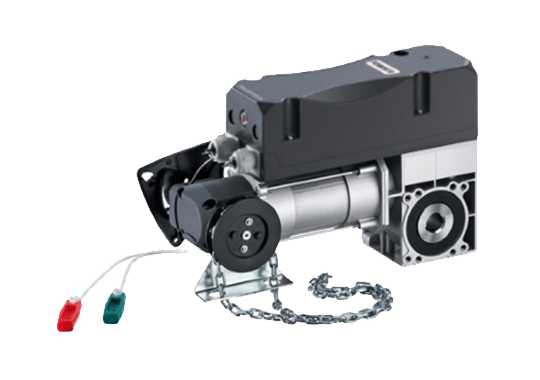

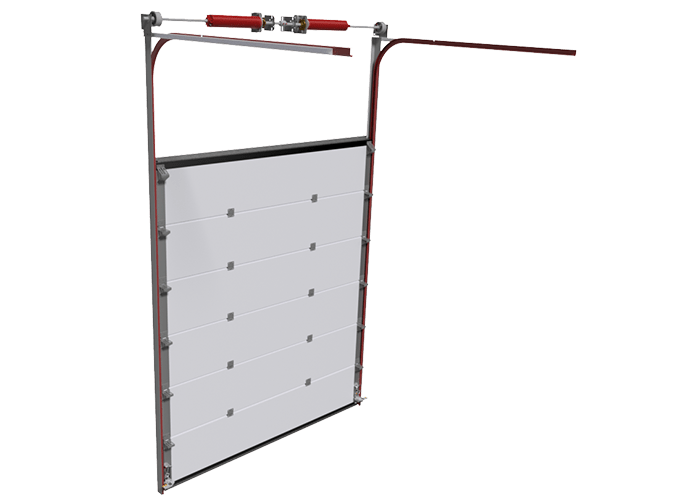

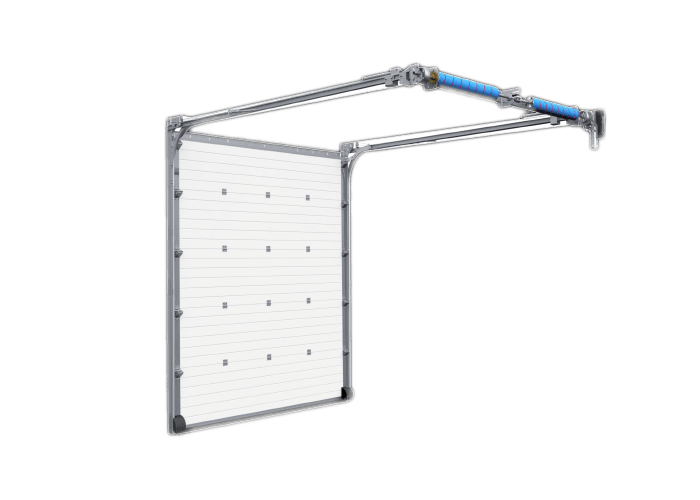

Driving low in front (F)

Guiding at an angle (K)

Vertical guidance (V)

Driving low back (LHR)

Energy efficiency

Safety in use

Tailor-made product

Safe panels

An interesting solution is the „finger protection” system, which is present at the panel joints. The special shape of the panels provides protection against fingers being trapped when opening and closing the door by hand.

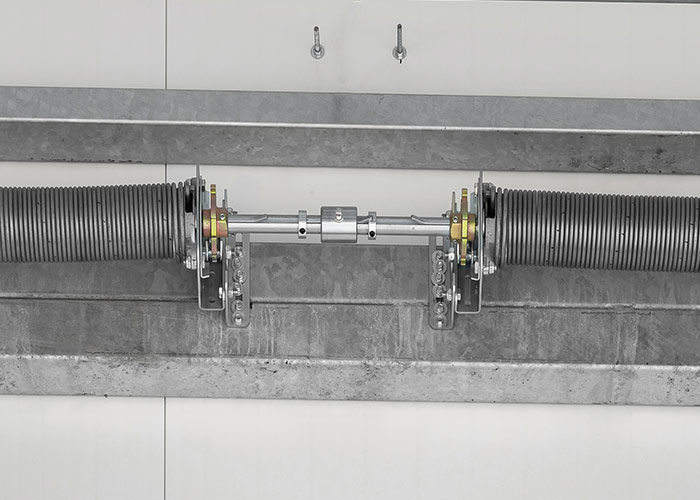

Protection against spring fracture

All our industrial sectional doors are equipped with a special safety device that prevents the door from falling rapidly in the event of a spring breakage.

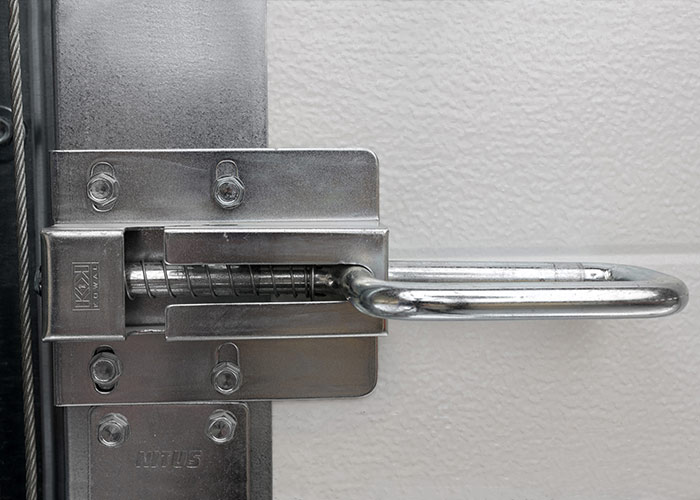

Protection against wire breakage

The frequency of use of industrial doors necessitates the use of an additional safety device to eliminate the phenomenon of the door falling if one of the cables breaks.

Manual override

The primary means of securing an industrial door against intrusion is a manual deadbolt, standard on manually operated doors, which effectively prevents an externally closed door from being lifted.

In industrial facilities, service doors installed in the door are an extremely practical solution. They allow access to a room without having to open and therefore operate the door. The service door is visually indistinguishable from the door leaf, creating an absolutely coherent design. A service door opening sensor is standard for automatic industrial doors. This element prevents the drive from starting up if the door is left open. In addition to the classic „solid” door, we offer our customers a service door with the option of a glazed section. In addition, we are able to manufacture doors with a low threshold of just 25 mm.

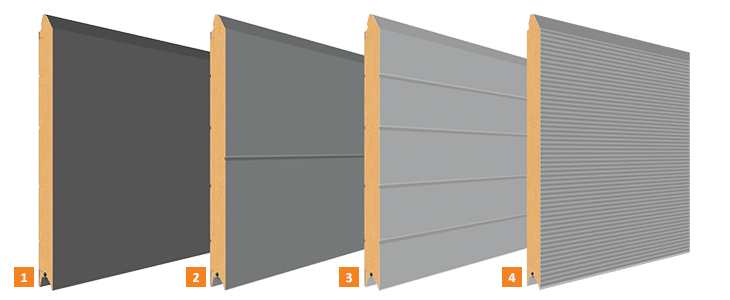

Industrial doors are available in four types of embossing. Choosing one of them allows you to emphasise the original design of the product, thus guaranteeing an attractive appearance for any architectural composition.

1. without embossing

2. single rib

3 Narrow rib

4 V-brace

Painted colours

NOTE: The colour representation shown below may differ from the actual veneer appearance . In order to determine the actual appearance of the veneer, please use the aluplast decorative foil sample chart.

For the purposes of industrial buildings, we can replace the steel panels in sectional doors with „glazing”, which provides significant light to the interior of the premises. The construction of glazed sections is based on aluminium profiles filled with double-glazed acrylic glass. Thanks to the modular construction of industrial doors, our customers are given complete freedom in shaping the final appearance of the product. This means that the number of glazings, their shape and arrangement depend on the customer's preferences. The door elements, both aluminium and steel panels, can be combined and painted in any RAL colour.

SEE ALSO

Let's talk about the offer

Our advisor will answer your questions and take your order.

debica@kmokno.pl

Phone

690 997 751

Address

DĘBICA BRANCH

1 Rzeszowska St.

39-200 Debica